90% Reduce inventory work time. More efficient shop inventory management

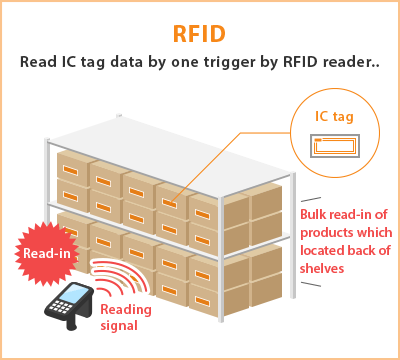

RFID is increasingly used in logistics today for the way it allows for contactless reading and writing of data and importing multiple tags in batches. Processes like incoming inventory inspections and inventory, which used to be done one at a time, can now be done in bulk, greatly improving the efficiency of work processes.

RFID tags affixed to pallets and product cases are used for logistical administration. These can also be affixed to products to enable tracking the entire flow of a product from the plant to warehouse, on through distribution, and then to the final shop, as well as identifying what shelf it is on and whether it was taken to the register. This also allows for drastically improving the process of counting products one by one when doing inventory in-store.

- Before

- After

Benefits to deployment

-

- 1Inventory

- Cut down the time spent on inventory for several thousands of items in shops. Allows just 2-3 people to do the process in 1-2 hours.

Using RFID tags to search for items successfully cuts down work time to 1/10th of manual processes.

-

- 2Shipment registry

(at shop) - Using RFID tags for shipment also cuts down on 74% of processes. The biggest contribution is not in scanning time itself, but in having to resort items after scanning them, a process that can now be abbreviated.

- 2Shipment registry

-

- 3Anti theft system

- RFID tags can be used as anti-theft tags in order to ensure that items are not taken. This also eliminates need to remove anti-theft tags at the register, cutting down on wait time for customers.

-

- 4Shipment/Receive

(logistics warehouse) - Instead of opening boxes one at a time to inspect their contents on arrival, the same process can be achieved within 10 seconds/box. This allows for rapid intake of shipments and prevents unintended export.

- 4Shipment/Receive

Case Study

Japan Pallet Rental Corporation.

- Achieving both asset management and advanced client services Mighty Cube RFID technology supports the RFID systems used by Japan Pallet Rental Corporation, a leader in the industry.

- With a forty year history in rental and supply of pallets, Japan Pallet Rental Corporation (hereafter, “JPR”) considers offering client-centered usability to the logistics industry essential for the creation of better lifestyles. To that end, it was the first in the industry to operate an RFID-based inventory management system compliant with EPCglobal standards. The RFID tags [PM3 Pallet Tags] used in this system were jointly developed by JPR and Mighty Guard with assistance from Impinj, Inc. (USA). An RFID tag antenna is installed on a plastic pallet to achieve a proprietary UHF Gen2 RFID system that offers both high read fidelity and durability. Affixing these RFID tags to plastic pallets and tracking their movement in real time allows for analyzing the distribution routes of rental pallets and curbing unauthorized use. As a result, this leads to better use of assets and a system for providing clients with pallets in a speedy and optimized fashion.

Change due to introduction

-

- Preventing loss of assets and curb need to procure new items

- Switching from overall inventory management of rental pallets to individual management of each unit allows for tracking in real time how many pallets are being lent out to what client and where. This allows for clearly identifying at what point in the supply chain an item was lost, preventing loss of assets and also ensuring efficient use and reuse at other sites. This also reduces the costs associated with procurement of new pallets, cutting down on expenses.

-

- Visualizing where pallets are placed

- Visualizing in real time where pallets have been placed lets you efficiently get quick advice on rental pallets when you need it.

-

- Improving uptime of depots

- We optimized inventory at 90 depots nationwide and have improved the fidelity of operations across the board.

JPR attaches RFID tags to its rental pallets and visualizes their movement, using this to develop procurement and supply plans, as well as support its clients. When pallet inventory arrives at its depots, it can analyze which item is bound for which client and which have been returned. This lets them determine how its clients use the pallets and predictively forecast things. This data is also used as the basis for various proposals they make to clients for the efficient use of rental pallets. As a result, clients can utilize rental pallets in an optimal fashion and at the minimum cost, achieving the true ends of the rental pallet system.